Supercritical CO2 extraction

processes development.

Fine-tuning a process.

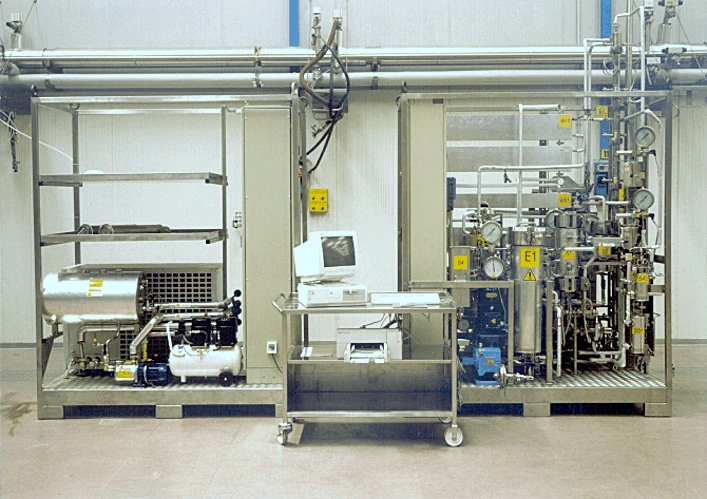

We at Exenialab are excited to offer you a state-of-the-art solution that will revolutionize your processes and take your business to new levels! Our top-of-the-line supercritical CO2 equipment manufactured by Separeco is designed to be able to develop any type of supercritical CO2 process. We know that you need to view the extraction process of your material before you decide to adopt this new technology. That is why we have developed numerous feedstock tests that are sure to impress you and convince you of the great value our process brings to your operations.

We are firmly committed to creating new frontiers in supercritical CO2 extraction. Our rigorous raw material testing, accentuated by comprehensive analytical evaluations and rigorous purification techniques, produces an unprecedented product characterized by its remarkable effectiveness and economic viability.

Supercritical CO2 extraction processes: the raw material

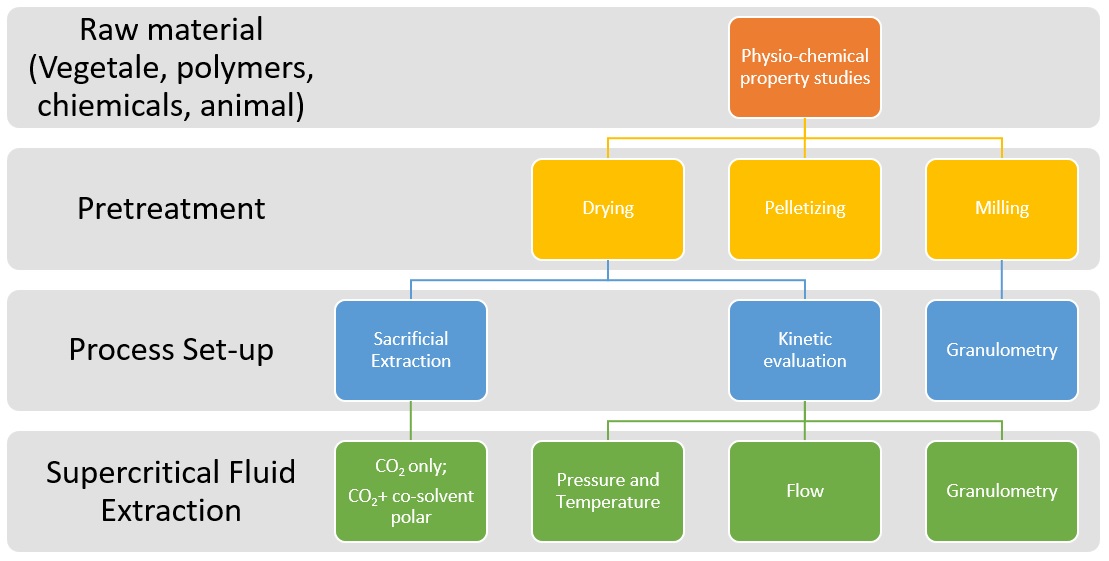

As we begin our quest toward the pinnacle of supercritical CO2 extraction processes, we embark on a journey characterized by a rigorous determination of the raw material that will undergo the extraction process. Our repertoire is characterized by a wide range of materials including plant, animal, inorganic, polymer and oil, each of which has its own distinct attributes. Consequently, meticulous selection is required to align the feedstock with the specific objectives of the supercritical CO2 extraction processes and ascertain the precise placement of the target compound within the chosen feedstock.

Supercritical CO2 extraction processes: the pre-treatment

Our preliminary stage is characterized by a rigorous procedure involving the sacrificial evaluation of the selected raw material. This evaluation has the fundamental purpose of establishing the key extraction parameters and conditions for the singular goal of achieving the optimal yield and unparalleled quality of the target compound. As always, we start from the scientific literature to evaluate the extraction conditions. The parameters of supercritical CO2 extraction processes must be verified on the raw material itself, once pretreatments have been carried out. Drying, grinding, and other pretreatments have an important impact on the raw material, affecting the efficiency and quality of the extract. Extraction method development is a complex process involving numerous extraction cycles to highlight the influence of various parameters on the final extract.

How pressure and temperature affect supercritical CO2 extraction processes

To achieve the set goal, our highly qualified engineers have been assigned the crucial task of organizing and executing precise pressure tests with great attention to detail. The main objective of these tests is to identify the optimal pressure and temperature range that favors the extraction process. The target solubility is the result of the pressure/temperature process parameters. The interaction between pressure and temperature is critical to optimize extraction with supercritical CO2. It allows us to selectively extract valuable compounds from your raw material.

How CO2 flow rate affects supercritical CO2 extraction processes

A comprehensive investigation of extraction kinetics serves to facilitate the identification of crucial information related to the extraction rate and the inherent dynamics of the process. Very often, by mistake, operators push the CO2 flow rate as high as possible, thinking they will have a better yield. Very often, however, exactly the opposite happens: low flow rates produce more extract. This counterintuitive effect is the result of several converging factors such as contact time and the wormhole effect. Click here to visit Separeco's website.

How material size affects supercritical CO2 extraction processes

Particle size tests are equally significant, as they provide valuable information on the impact of raw material particle size on extraction efficiency. Controlling material size is essential for optimizing the efficiency of supercritical CO2 extraction processes. Grind size changes the total material/solvent exchange surface area. Smaller sizes generate larger exchange surfaces, but great attention must be paid to how the raw material is prepared. Generally, coarse grinding produces excessively large particles, negatively affecting efficiency because of the reduced exchange surface area. Conversely, ultrafine grinding may produce dust that is too fine, which may enter valves and filters and clog them. It is critically important to find the right balance between these two opposites.

Parameter optimization of supercritical CO2 extraction processes

This in-depth review includes an exhaustive analysis of temperature tests, which allows us to accurately determine the temperature range that maximizes extraction efficiency while ensuring prudent preservation of the integrity of the coveted target compound. In addition, we conduct rigorous evaluation of flow tests to refine process parameters, thus ensuring efficient and uninterrupted operation with minimal production interruptions. By skillfully optimizing process parameters to accommodate a wide range of input materials, we strive to impart the most effective extraction possible.

Data tracking of supercritical CO2 extraction processes

The data logger collects all data from the instruments installed in the supercritical CO2 extractor. When possible, valve position and pump start stop are also collected. The data are loaded into the evaluation software, comparing the influence of all parameters on supercritical CO2 extraction processes. The best parameters are selected and used for final extraction before writing the final report for the customer. Graphical analysis of the parameters of the supercritical CO2 extraction processes is essential to understand the behavior of the raw material under different extraction conditions.

Post treatments

After the supercritical CO2 extraction processes, a complete and thorough analytical evaluation of the extract is then carried out, paying close attention to even the most minute details of its characteristics. Fundamental among these meticulous evaluations is the critical determination of the lipophilic or hydrophilic nature of the compound, the results of which play an essential role in tailoring the extraction process to maximize the desired result. In cases where essential oils are present within the extract, their qualitative and quantitative analysis becomes essential research, as it is imperative to ensure that the final product meets the highest quality standards. For aqueous extracts, pH measurements are conducted with unparalleled precision to ensure strict adherence to predetermined specifications.