Supercritical CO2 extraction benefits.

Versatility and sustainability in one process.

With small adjustments it is possible to significantly improve the quality of your extracts. Unlike liquid solvents, supercritical CO2 extraction allows you to modulate selectivity, adding a new dimension in which to move.

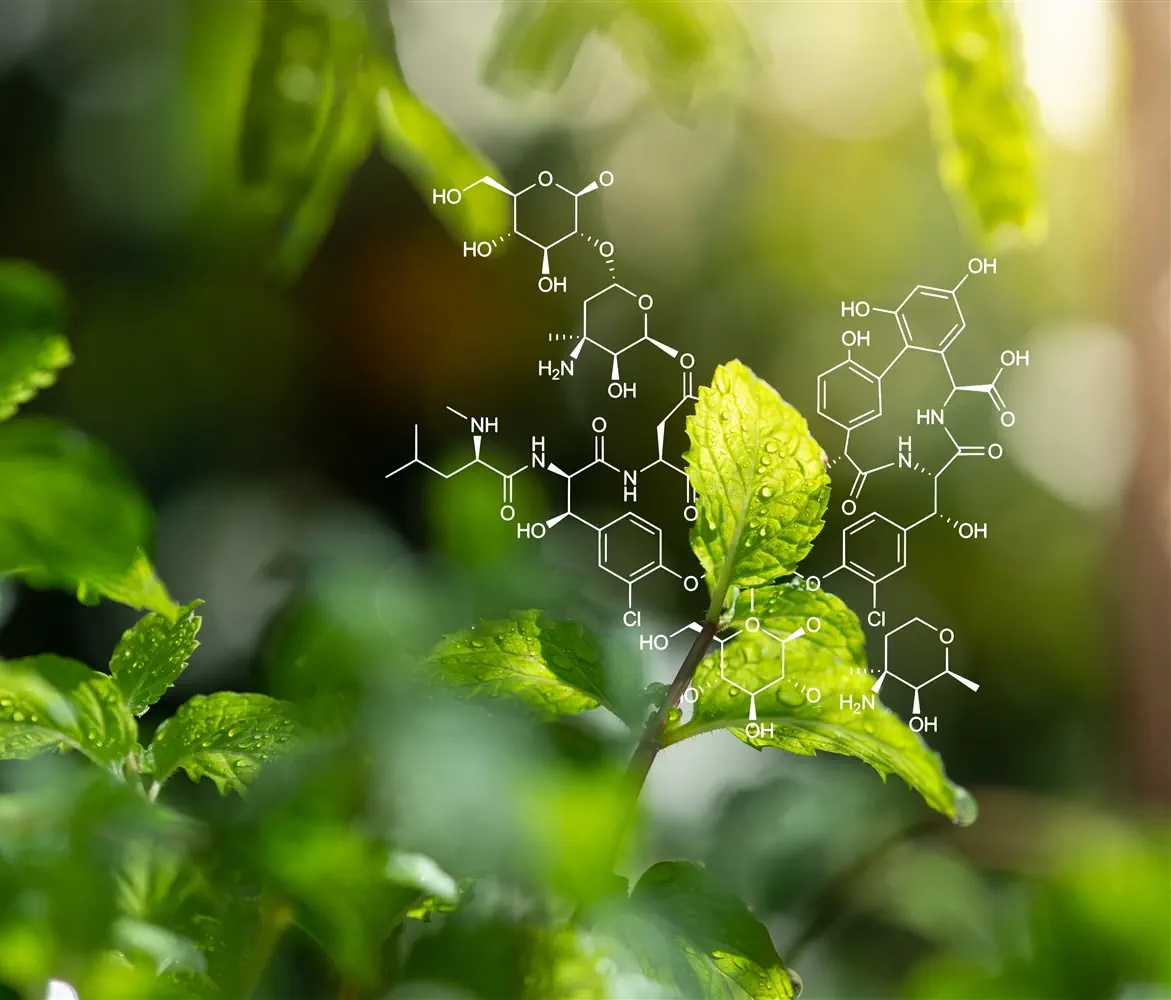

It's like moving from two-dimensional to three-dimensional drawing: not only do you move far and wide, but you can also move in depth. Using supercritical CO2 extraction will open up new horizons, new process opportunities, without losing sight of the advantages deriving from the use of a GRAS (Generally Recognized As Safe) solvent, accepted and approved by the American FDA and the European EMA. A world of new opportunities to discover.

Supercritical CO2 extraction of thermolabile substances

Supercritical CO2 extraction processes generally take place under mild extraction conditions and at low temperatures; this allows for the recovery of thermolabile substances, i.e., substances that are heat-sensitive and that in other contexts would be degraded and partially destroyed by high temperatures. In addition, the use of high pressures from 80 to 350 bar, but can go even higher (useful in a few limited cases) allows the solvent strength to be modulated and make the CO2 selective for some substances and not others. This feature makes it possible to potentially obtain lipophilic extracts with a controlled or otherwise dampened degree of undesirable substances

One example: supercritical CO2 extraction of chlorophylls

f you want to obtain an extract from lotus leaves, you can limit the extraction of chlorophylls that would give a green or black color to the extract by limiting the pressure applied. Small steps such as this at the process planning stage could eliminate time-consuming and costly post-processing steps. In fact, activated carbon filters are generally used to separate chlorophylls by dissolving the extract in a suitable solvent and then clarifying the solution through the aforementioned filters.

Savings from the use of supercritical CO2 for extraction.

With supercritical CO2 extraction, it is possible to cancel many post-process steps and save on the purchase costs of ethanol, activated carbon filters, and the important process costs associated with these purification steps. The disposal costs of ethanol and activated carbon filters are, especially the latter, very high. Finally, 95 percent of the CO2 used in one extraction cycle is recompounded for reuse in the next process, so there is not a large release of carbon dioxide and in any case even this small amount can be recovered and reused easily (generally happens in industrial plants). Therefore, we can say that the extraction of supercritical fluids, such as supercritical CO2, is a sustainable and green process.

What are the steps to perform supercritical CO2 extraction

While in the laboratory for small benchtop systems, from 20 ml to 250 ml volume for the extractor, manual equipment are generally used, in production as well as in the raw material analysis laboratories of manufacturing companies, fully automated plants that track process data are preferred. These plants are equipped with automation that manages the process as a whole, using recipes specially programmed by the operator. The software and configuration closely match that of the production plant, and allow for testing and fine-tuning of process parameters before going into production with larger plants. Once tested, production recipes are transferred to the production plant, maximizing performance and minimizing waste. Separeco, the Piedmont-based manufacturer of supercritical CO2 plants, has a very wide range of models in its catalog for all needs. Click here to visit Separeco's website.

The processing cycle of supercritical CO2 extraction

The steps to proceed with the extraction are very few and simple:

- Loading the raw material into the extractor basket.

- Loading the basket into the extractor.

- Start of the extraction cycle.

- Collection of extracts.

- Depressurization and basket change.

Supercritical CO2 extraction processes versatility

Extraction processes in SCFs (Super Critical Fluids or Supercritical Fluids), and particularly with supercritical CO2, can be very versatile, that is, they are able to address different jobs and activities. Remaining in the area of lipophilic extraction, CO2 is unrivaled in terms of effectiveness, especially since it can be extracted from numerous oily or nonpolar-rich matrices. For example, it is possible to carry out a chia oil production campaign and then produce bitter orange essential oil extracts, all with the same system, after a deep cleaning cycle. SC-CO2 is also versatile because it allows drying processes, cold pasteurization processes, or is used in the production of innovative aerogels because it can eliminate solvents used for synthesis extremely easily and quickly. Finally, to cite an industrial use case, supercritical CO2 is used for the production of certain polymers (plastics) that are suspended in a fluidized bed of liquid or supercritical CO2 before being pelletized or spun for the production of virgin PE and PP or PET polyolefin granules